News

Application of Infrared Sensing Technology in Flame Detection

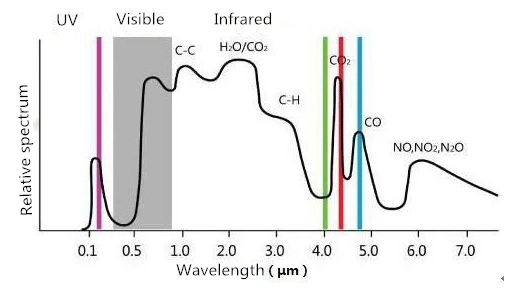

The combustion of any substance is inevitably accompanied by a localized increase in temperature, which generates a certain intensity of electromagnetic radiation in the space around it. The radiation spectrum generated during the combustion of substances has its own inherent characteristics, the use of sensors to measure the radiation signal, we can detect the flame, which is the basic principle of the flame detector.

Different substances emit different red and ultraviolet spectra when they burn, and three peaks of flame radiation can be clearly seen in the flame spectrum.

One of them is the ultraviolet section 0.28μm below the part, the other two are infrared section 4.3μm and 4.6μm near the surface of the daylight radiation curve in these three bands is exactly in the trough position.

Usually the center wavelength of the filter in the flame detection band is around 4.3μm and 4.4μm. Different bandwidth designs can detect the mid-infrared wavelength infrared signals in the range of 4.0~4.6μm radiated by CO2 and CO gases emitted from the combustion flames of hydrocarbons, and different sensors can be selected according to the spectra emitted by different fuel combustion.

Selection of Flame Sensors

For the ultraviolet wavelength of 0.185~0.260μm generated in the flame combustion, a solid material can be used as the sensitive element, such as silicon carbide or aluminum nitrate.

For the infrared wavelength of 2.5~3μm generated in the flame, aluminum sulfide material can be used as the sensor

For infrared light generated in the flame at a wavelength of 4.4~4.6μm, sensors made of lead selenide or aluminum tantalate can be used.

In the 3.8μm and 5.0μm near the flame radiation is obviously weaker, commonly used in the flame monitoring channel, auxiliary channel, for monitoring non-fire hot body radiation, solar radiation.

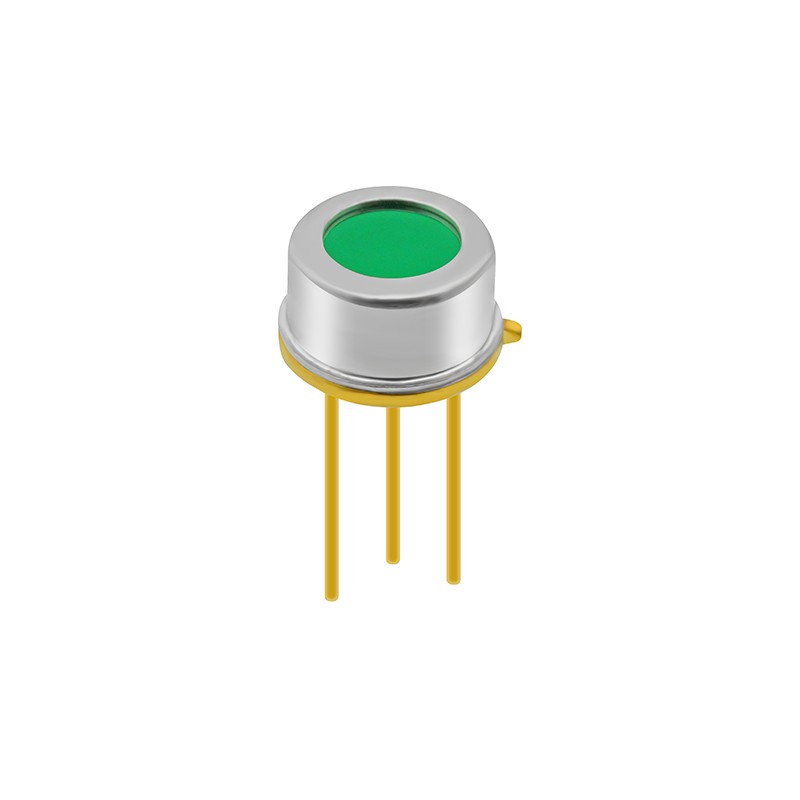

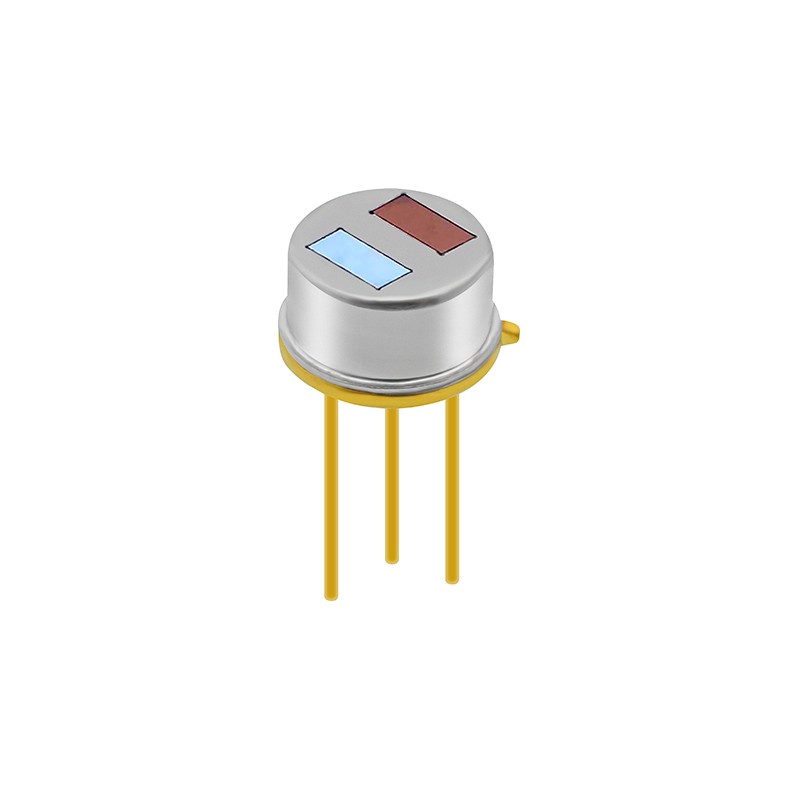

Infrared Pyroelectric Flame Sensor

Infrared pyroelectric flame sensor utilizes pyroelectric effect and adopts lithium tantalate single crystal as the sensitive element material. Curie temperature of lithium tantalate crystal material in 600 ℃ or more, the relative permittivity is small, than the detection rate is high, in a wide range of room temperature, the material pyroelectric coefficient of change with the temperature is very small, the temperature change rate of the output signal is only 1-2 ‰, the temperature stability of the sensor performance is very good, and in the range of wavelengths of 1 ~ 20 μm spectral response consistency is very good.

Selection Chart

Technical Parameter | Symbol | Typical value | Unit | |||||

Model no. | LCF001 | LCF002 | LDF001 | LVF001 | LVF002 | LVF014-HD | ||

Window size | Ф5.5 | Ф5.5 | Ф5.5 | Ф5.5 | Ф5.5 | 2-2×3.6 | mm | |

Element size | As | Ф2.5 | 2.25×2.25 | Ф2.5 | Ф2.5 | 2×2 | 2-2.5×2.5 | mm |

Electrical Time Constant | τE | 6.0 | 3.0 | 3.0 | s | |||

Thermal Time Constant | τT | 50 | 150 | 200 | 200 | 200 | ms | |

Offset Voltage | Vs | 0.4-0.7 | 0.4-0.8 | V | ||||

Drain Voltage | Vd | 5-26 | 4.5-5.5 | 2-15 | 2-15 | 2-15 | V | |

Recommended supply voltage | Vr | 9 | 5 | V | ||||

Field of View | FOV | >110 | >110 | >110 | >110 | >110 | ° | |

Noise Density ((10Hz,BW1Hz,25℃)) | Vn | <70 | <60 | >170 | <130 | <120 | μvrms/Hz1/2 | |

Voltage Responsivity (Without Filter)(500K, 10Hz, 25℃) | Rv | >200,000 | >400,000 | >160 | >160 | V/W | ||

Detectivity(Without Filter) (500K, 10Hz, BW 1Hz, 25℃) | D | >4.4E+08 | >4.4E+08 | >4×108 | >4×108 | >4.0E+08 | Cm Hz1/2/W | |

Detection distance (Alcohol fire 0.1m2) | L | >30 | m | |||||

Working temperature | -40℃~+80℃ | ℃ | ||||||

CMOS OpAmp | 400X | |||||||

Related News

- Reliable Semiconductor gas sensor 2025-05-15

- About VOCs 2025-04-03

- Home Gas Leak Detection Solutions - Semi 2025-03-31

- CO monitoring in underground garages 2025-03-27

- About dust sensors 2025-03-25

Categories

Contact us

HJP Technology Co., Ltd

Contact:Angela Sun

Mobile:+86-18603812197

Email:[email protected]

Add:No.11 Zhengshang Road, Zhengzhou, 450007, China

angela

angela